40719: Kelp Industry in Uig

The kelp industry in Lewis had a short-lived but productive existence from about 1760 to 1836. It gave the people an opportunity to earn some money (useful for paying their rent) and proved lucrative for the proprietor. Between 1812 and 1835 the proprietor of Lewis made an approximate profit of 37,000 from the sale of kelp. In 1833 Uig produced 226 tons.

The parish of Uig was the first important kelp-making area and the inhabitants developed such expertise that they also kelped in Lochs, Harris and Uist. They had been coerced into this by the factor, Mr Gillanders, as it was evidently a choice between kelping and joining the army.

Kelp making was the conversion of seaweed into calcined ash for the production of soda and iodine. It was an unhealthy, unpleasant and onerous labour at all stages. Forty creels of seaweed were needed to make one hundredweight of ash.

The cutting of seaweed from the rocks began about 6th June every year, and the burning ended about 17th July, a period of some six weeks. At ebb tide, the seaweed was cut as quickly as possible and thrown into a circular ring of heather rope. As the tide flowed, the raft of seaweed floated and was dragged ashore.

Deep bays around Vuia Bheag allowed boats to land with the seaweed and then to load the finished blocks.

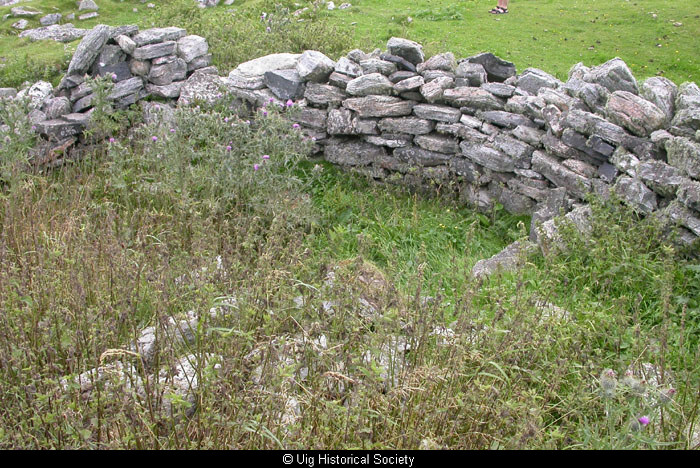

Once landed, the seaweed was spread out to dry and Vuia Bheag was reputed to have a good sgaoilteach or drying area. When dry, the seaweed was burned in the kilns. The sides were formed by stones with trenches to hold peat and to allow a draught of air. From the time it was lit it required constant attention – and was ‘ruinous to the eyesight and quite repugnant’.

It was stirred until it acquired the consistency of moist clay. It was allowed to cool and then covered with seaweed and clods of earth to protect it from the weather. When cold, it was cut into large blocks for shipping.

The kelp was weighed on board by the kelp officer at twenty two and a half hundredweight to the ton to allow for any impurities such as sand or gravel. From Vuia Bheag the kelp blocks would be taken to Loch Drovinish for loading. The ground officers acted as kelp superintendents, their chief concern being the quality and quantity of the kelp, with little thought given to the conditions of the workers.

It was asked of one Donald Munro: An e duine math a bha ann an Domhnall Munro?

Came the response: Se a dh’innseas sin grunnd Loch Drobhanais agus latha a’breitheanais.

This referred to his habit of cruelly dumping into the sea blocks of kelp which he judged to be inferior.

Individuals were paid from 30 shillings to 3 guineas a ton. Lewis factors paid the ground officers who settled with the tacksmen and tenants before the rent was due.

After 1882 kelp was no longer used for the manufacture of soap. It continued to be produced on a small scale for iodine. The men received one shilling and sixpence per day and the women received much less.

In the summer of 1850, necessity forced twenty five families around Little Loch Roag, Bernera, Callanish and Breasclete to manufacture twenty six tons for which they received 2 a ton.

Uig Historical Society

See also the account of kelp manufacture in Harris from the Statistical Account of 1799 and Angus ‘Ease’ Macleod’s information on the industry.

Details

- Record Type:

- Story, Report or Tradition

- Type Of Story Report Tradition:

- Report

- Record Maintained by:

- CEU